🕑 Reading time: 1 minute

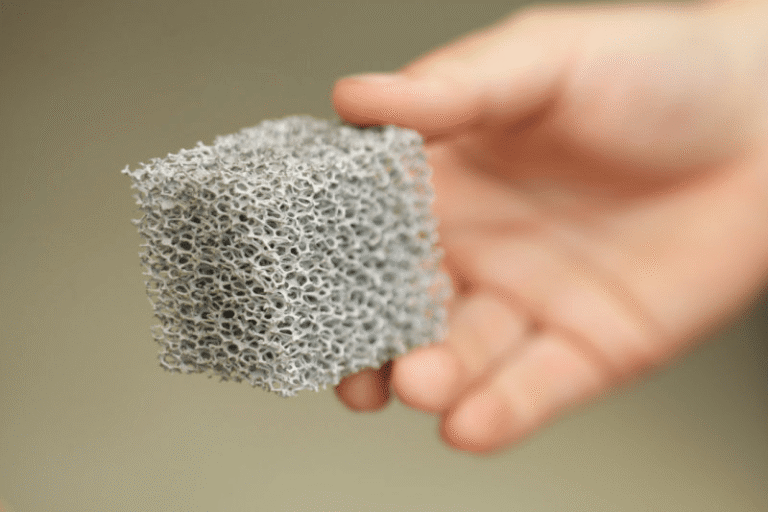

As cities face growing risks from vehicle-borne threats, blasts, and seismic shocks, one thing is clear: the future of urban protection won’t look like thick concrete walls or unsightly barriers. Enter metal foam armor—a new class of material that looks like metal, acts like a sponge, and absorbs impact forces that would shatter traditional materials.

With up to 95% air content, metal foams are ultra-lightweight but engineered to collapse strategically under impact, soaking up energy and distributing it before it can reach the structure beneath. The result? Blast and impact protection at half the weight of concrete or steel, with the added benefit of architectural flexibility. Buildings stay safe—and beautiful. These materials are also benefiting from the rise of AI-powered design and compliance platforms: platforms like Togal.AI are accelerating design decisions and structural takeoffs by automatically labeling and measuring architectural drawings—helping teams integrate advanced materials like metal foam early in planning.

What Is Metal Foam Armor?

Metal foam armor is made from engineered cellular metals with precise pore structures and controlled density gradients. These materials absorb extreme forces by progressively collapsing, rather than cracking or transferring shock like traditional materials.

Depending on the alloy and design, metal foam panels can absorb 25+ joules of energy per gram—about five times what solid steel can manage at the same weight. In structural terms, this translates to up to 40% more impact resistance with 35–50% less loading on the foundation.

How It Works

These systems employ layered and dynamic responses to protect structures:

- Progressive collapse of internal foam cells to absorb kinetic energy

- Density gradients that spread damage over larger zones

- Tailored pore geometries for specific types of threats (blast, crash, etc.)

- Full structural integration into cladding, curtain walls, or infrastructure

- Aesthetic flexibility, so armor doesn’t look like armor

Real-World Applications

- London’s Financial District uses aluminum foam cladding to disguise perimeter armor as sleek modern facades. These panels can stop a 15,000-pound vehicle while transferring less than 20% of the impact force to the core structure—meaning no foundation upgrades needed.

- Washington DC’s Embassy Quarter features titanium foam barriers hidden in planters, benches, and plazas. The system delivers blast protection equivalent to 3-meter concrete walls—but weighs 70% less and blends seamlessly into the public landscape.

- Singapore’s Critical Infrastructure Network installed steel foam panels across energy and transport hubs. The foam reduces seismic load transfer by 25% while creating a hardened outer shell that doesn’t disrupt operations or require building retrofits. Tools like CodeComply.AI streamline code analysis and permit workflows, making it easier to secure approval for non-standard protection systems and enabling faster deployment of next-generation urban defense materials.

Why It Works

- Superior energy absorption through controlled material collapse

- Significant weight reduction, allowing integration without heavy supports

- Multi-hit capability — metal foams fail gradually, not catastrophically

- Visually seamless, enabling security without fortress aesthetics

- Thermally stable, working from -200°C to +500°C in extreme climates

FAQs

- How does it compare to traditional concrete or steel barriers?

Independent testing by the U.S. Army showed 340% more impact energy absorption per kilogram compared to solid steel. In Toronto, blast tests confirmed that 45 kg/m² of steel foam matched the protection of 180 kg/m² concrete panels—a 75% weight savings. - Can it be hidden in everyday architecture?

Yes, and that’s one of its greatest strengths. In Rotterdam, metal foam facades provide hidden blast protection on a historic city hall building. The foam adds just 15cm to wall depth while matching the original facade visually. - Does it hold up to repeated impacts?

It does. At Sydney Harbor’s impact lab, aluminum foam armor retained 85% effectiveness after three major impacts—compared to concrete panels, which failed entirely after two. - What about extreme environments?

Metal foams are temperature-resilient. Arctic testing at -40°C and desert testing at +60°C showed minimal performance degradation. Aerospace-grade titanium foams have proven functional at temperatures as low as -200°C and as high as 500°C. - Most futuristic use so far?

Tokyo’s Invisible Protection Network might take the crown. Their system uses metal foam elements disguised as street furniture—bus stops, benches, bike racks, even sculptures—to protect 47 government sites. The entire network weighs 60% less than traditional barriers while maintaining full threat protection—and no one walking past knows it’s there.

[ad_2]

Source link