🕑 Reading time: 1 minute

Imagine a building that reshapes itself in real time—its skin pulsing with light, opening to let in a breeze, or sealing tight against heat, all without a single moving part in the traditional sense. Welcome to the world of magnetized steel skins, one of the most exciting and disruptive innovations in architecture today.

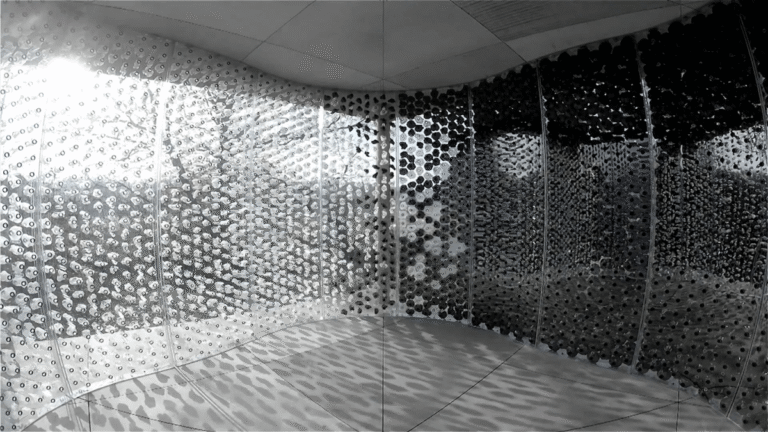

These facades are made of ferromagnetic panels—thin, flexible steel elements that are guided by electromagnetic fields rather than motors. Controlled by sophisticated algorithms and responsive sensors, they can change shape in under 3 seconds, react to sunlight, wind, and even events, and hold their shape with near-zero energy. They combine the strength of steel with the precision of digital movement and the grace of natural response.

What Are Magnetized Steel Skins?

These systems use specially engineered steel panels that respond to magnetic fields generated by an embedded control grid. When activated, the panels shift to pre-programmed positions based on environmental conditions or design intent. Unlike motorized or pneumatic systems, magnetized skins are silent, scalable, and nearly maintenance-free, since there’s no mechanical wear.

They use power only during transitions, not to hold position—making them radically more efficient than traditional kinetic systems. In practice, buildings using these facades have reported 18–25% reductions in energy consumption, especially in lighting and HVAC loads.

How It Works

Under the surface, it’s all high-tech orchestration. The facade grid emits variable electromagnetic fields, each calibrated to influence its assigned panel. Software algorithms dictate when and how to shift panels based on sun tracking, temperature, wind, or even scheduled visual effects. Real-time sensors feed performance data back into the system, allowing continuous optimization.

There are no hinges, motors, or clunky mechanisms. The motion is quiet, clean, and precise—able to position thousands of panels to within less than a millimeter of accuracy, synchronized across a building’s entire surface.

Global Examples Leading the Way

- The Kinetic Institute in Rotterdam uses over 2,800 magnetized steel panels to manage daylight dynamically. The building maintains consistent interior lighting levels and reduces artificial lighting needs by 42%, all while putting on a mesmerizing visual display across its south-facing wall.

- The Taipei Performing Arts Center uses a magnetized facade that transitions from opaque to porous in just under 3 seconds, offering natural ventilation during crowded events. Airflow improvements of nearly 400% have slashed HVAC demand and created a powerful experiential moment as the building “opens” before showtime.

- Melbourne’s Climate Response Tower shifts its facade based on temperature and solar angle. During peak summer, the panels close on sun-exposed sides, reducing heat gain by 63%. On cooler days, they reopen to harvest natural light and warmth, minimizing energy use year-round.

Why It Matters

These facades do more than just look futuristic—they solve real-world challenges in energy efficiency, environmental adaptability, and building expression. Their low operational energy, near-zero maintenance, and resilience to wind and weather make them practical as well as visionary.

They also eliminate the need for visible machinery. There’s no clatter, no hydraulic failures, and no mechanical wear. Once calibrated, magnetized systems can operate autonomously for years with only software updates.

Of course, the technology isn’t without its challenges. It requires precise calibration, deep integration into the building’s structure, and a well-planned power management system. Installation is not yet plug-and-play—but for high-profile, sustainability-focused, or tech-forward projects, the ROI in energy savings and public impact is substantial.

FAQs

- How much energy does it use?

Very little. For example, the Shenzhen Cultural Center’s entire facade transformation consumes only 1.8 kWh—less than running a dishwasher. Once set in place, the panels require less than 0.3 kWh per hour to hold position. - What happens in a power outage?

They fail safe. Systems are designed to default into a secure, weather-tight position using residual magnetism and gravity. This ensures passive protection without needing backup power. - Can they handle storms or strong winds?

Yes. Their magnetic holding strength actually increases under stress. The Auckland Harbourfront project’s facade withstood 105+ mph winds without displacement—performing better than many mechanical systems. - How precise is the movement?

Extremely. The Sydney Opera House expansion features over 4,700 panels that move with ±0.8mm precision, enabling fluid, wave-like movements that respond to sunlight, events, or scheduled patterns. - What’s the most innovative use so far?

The Beijing Media Headquarters—a full building-scale digital canvas with 29,000 magnetized panels. It displays moving visuals from over 2 kilometers away while also adjusting to optimize heat gain and ventilation, all using less energy than the building’s lobby lighting.

Source link